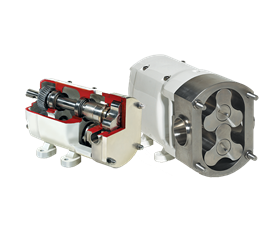

Rotorflo

Rotary Lobe Pumps

Rotorflo is a high-performance, compact pump requiring little maintenance, designed for hygiene-conscious industries. Franklin Electric is the only South African pump manufacturer to be awarded the European Hygienic Equipment Design Group (EHEDG) certification for its design of a rotary lobe pump.

-

Performance

- Flow rates up to 96m3/h

- Pressures up to 15 bar

Features

- Shafts are made of heavy-duty, large-sectioned stainless steel for less deflection and enhanced rigidity

- Helical gears time the main and lay shafts to maintain accurate clearances between the rotors. These clearances ensure high volumetric efficiency and increased suction

- Main bearings are of the standard taper-roller type

- Gearboxes are grease or oil lubricated

- Shaft sealing can be achieved by mechanical seal, packed gland or “O” ring, to suit application

- The spigotted rotor case is positively located on the bearing housing, eliminating loose dowels

- The 12-involute spline configuration ensures accurate positioning of rotors during assembly

- Low-shear characteristics protect delicate products

- Positive displacement technology ensures efficient transfer of all liquid viscosities

- The pumping chamber is fully swept, ensuring no product entrapment

- “O” ring seal profiled to the edge of pumping chamber. Most covers are flush, minimising areas where bacterial growth can occur

- All wetted parts are made from 316 stainless steel

- Full diameter porting supplied as standard. Fittings available to suit customer specification. Enlarged inlets for hopper feed also available

- Shimming external to gearbox to allow for quick and simple adjustments of rotor clearances when required

- The gear housing is manufactured from robust cast iron

- Keyed gears produce a positive drive to ensure that timing does not have to be reset when rotors are changed

- “O” ring seals on rotor keeps splines free of product contamination

- The front cover can be supplied with a pressure relief valve built in to protect against overload.

Applications

- Food

- Pharmaceutical

- Dairy

- Hygiene-sensitive applications

- For pumping shear-sensitive or viscous fluids

-

Brochures and Leaflets

Other